Complete Guide to Wiring Harnesses

What is a Wiring Harness and Why Is It Important?

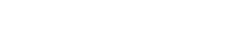

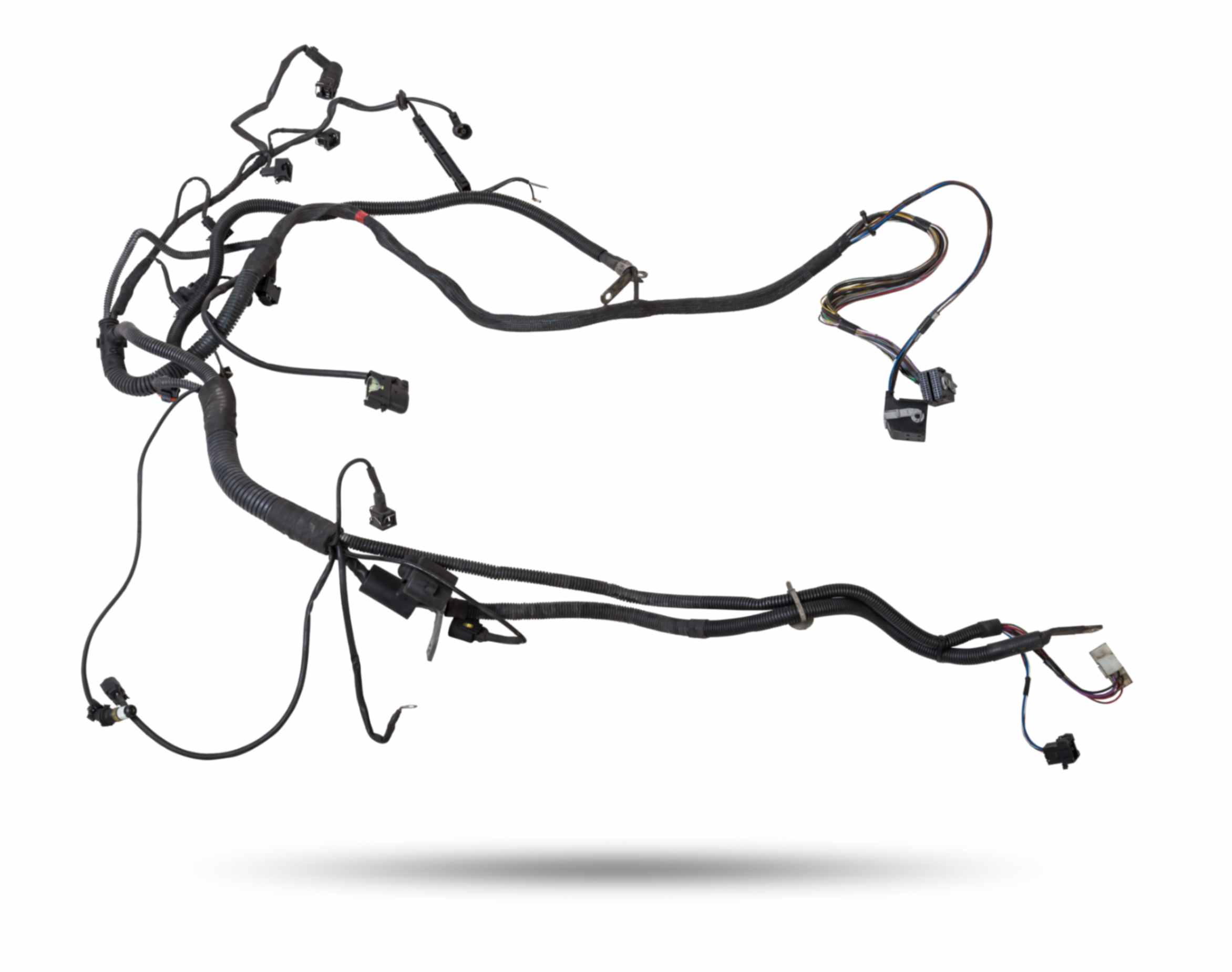

A wiring harness—sometimes called a cable harness, wiring loom, or electrical harness—is a carefully organized bundle of wires, connectors, and terminals. Its main purpose is to transmit electrical power and signals between different parts of a vehicle, machine, or device. Instead of installing hundreds of loose wires separately, engineers group them into a single system, wrap them with protective coverings, and route them through precise pathways.

This design brings several advantages. First, it improves safety. Exposed wires can rub against sharp edges, melt from heat, or short-circuit, but a harness shields them with insulation and protective tubing. Second, it increases durability. Vibrations, friction, and moisture are constant threats in automotive and industrial environments, and a harness helps protect against these conditions. Third, it saves time and cost during manufacturing and repairs. A pre-assembled harness can be installed quickly, ensuring that all electrical connections are secure and efficient.

Think of a wiring harness as the nervous system of a car. Just as nerves carry signals between the brain and muscles, the harness carries information between the vehicle’s electronic control units, sensors, lights, and power systems. Without it, modern vehicles and machines simply would not function.

Applications of Wiring Harnesses in Automobiles and Industry

Wiring harnesses are everywhere. You’ll find them not only in cars but also in trucks, motorcycles, airplanes, household appliances, and heavy machinery. However, the automotive sector is where they are most common and most essential.

In a car, for example, there are multiple harnesses, each dedicated to a system:

Engine wiring harness – Connects the engine control unit (ECU) with sensors, injectors, ignition coils, and fuel systems. Without it, the ECU cannot monitor or adjust engine performance.

Lighting harness – Powers headlights, taillights, indicators, and interior lights. These wires must withstand heat and exposure to the elements.

Dashboard harness – Links gauges, warning lights, and infotainment systems to the main power supply. It is often the most complex harness because it connects so many components.

Battery and charging harness – Carries electricity between the alternator, starter motor, and battery to ensure reliable ignition and power distribution.

In addition to automotive applications, wiring harnesses play a critical role in industrial equipment, medical devices, aerospace, and robotics. For instance, in manufacturing plants, harnesses connect sensors and automation systems that keep production lines running smoothly. In the medical field, they ensure that diagnostic machines and surgical equipment operate without electrical failure.

Because of this wide usage, the wiring harness industry is growing rapidly. Market analysts predict that the demand for advanced harnesses will increase dramatically with the rise of electric vehicles (EVs), autonomous driving technology, and the Internet of Things (IoT).

Main Components of a Wiring Harness

While a wiring harness may look simple from the outside, it is made of several carefully engineered parts:

Wires and Cables: These are usually copper or aluminum conductors insulated with materials like PVC or cross-linked polyethylene. Copper is the most common choice because it is flexible and highly conductive.

Connectors: Plastic housings with metal pins that allow wires to plug into sensors, control units, or other harnesses. Good connectors ensure strong electrical contact and prevent accidental disconnections.

Terminals: The metal ends that attach wires to connectors or components. Terminals are often crimped or soldered for strength.

Protective Looms and Tapes: Wrappings that bundle and shield wires against friction, vibration, and environmental hazards.

Fuses and Relays (in some harnesses): Added for safety, these protect circuits from overloads and ensure that power is distributed correctly.

Each component plays a role in reliability. If just one connector fails, an entire system—like the headlights or fuel injection—can stop working. That’s why choosing high-quality materials is crucial when manufacturing or repairing harnesses.

Standard vs. Custom Wiring Harnesses

Not all wiring harnesses are the same. Broadly, they fall into two categories: standard harnesses and custom harnesses.

Standard harnesses are mass-produced for specific vehicle models or appliances. For example, every Toyota Corolla of a certain year will use the same standard harness for its headlights. These are cost-effective, easy to replace, and widely available.

Custom harnesses, on the other hand, are designed for unique projects. Think of race cars, electric vehicle conversions, robotics, or heavy industrial machinery. These require harnesses that fit precise layouts and handle specialized electrical loads. Building a custom harness involves mapping out wire lengths, routing paths, and selecting the right protective coverings. Although they take more time and cost to produce, they provide unmatched flexibility and performance.

For businesses and individuals, the choice depends on the project. A regular car repair might only need a standard harness. But if you’re building a prototype EV or a high-performance racing vehicle, a custom wiring harness is the smarter option.

The Future of Wiring Harnesses

Technology is reshaping the wiring harness industry. As vehicles and machines become smarter and more connected, harnesses must handle higher voltages, faster data transfer, and more complex layouts.

For example, electric vehicles (EVs) require high-voltage harnesses to safely carry electricity between the battery pack, inverter, and motor. Traditional copper wires are heavy, so many manufacturers are experimenting with aluminum conductors and lightweight composites to reduce vehicle weight and improve efficiency.

In addition, fiber optic cables are beginning to replace some copper wires in advanced harnesses, especially where high-speed data transfer is needed. This is critical for autonomous vehicles, which depend on real-time communication between cameras, sensors, and onboard computers.

Looking ahead, wiring harnesses will continue to evolve as one of the most important components in modern technology. Without them, the future of electric mobility, automation, and connectivity would not be possible.

Conclusion

A wiring harness may seem like a simple bundle of wires, but it is truly the nervous system of every modern vehicle and machine. From starting the engine to powering headlights, radios, and safety systems, wiring harnesses keep everything connected and working reliably.

If you’re working on an automotive repair, an EV conversion, or an industrial project, investing in a quality wiring harness is essential. It ensures safety, reduces downtime, and extends the lifespan of your equipment.

👉 Explore our range of connectors, terminals, and custom wiring harness solutions to get started on your next project.